[ad_1]

Etsy, an internet market for distinctive, handmade, and classic gadgets, has

seen excessive development over the past 5 years. Then the pandemic dramatically

modified consumers’ habits, resulting in extra shoppers buying on-line. As a

consequence, the Etsy market grew from 45.7 million consumers on the finish of

2019 to 90.1 million consumers (97%) on the finish of 2021 and from 2.5 to five.3

million (112%) sellers in the identical interval.

The expansion massively elevated demand on the technical platform, scaling

site visitors virtually 3X in a single day. And Etsy had signifcantly extra prospects for

whom it wanted to proceed delivering nice experiences. To maintain up with

that demand, they needed to scale up infrastructure, product supply, and

expertise drastically. Whereas the expansion challenged groups, the enterprise was by no means

bottlenecked. Etsy’s groups have been in a position to ship new and improved

performance, and {the marketplace} continued to offer a glorious buyer

expertise. This text and the subsequent type the story of Etsy’s scaling technique.

Etsy’s foundational scaling work had began lengthy earlier than the pandemic. In

2017, Mike Fisher joined as CTO. Josh Silverman had lately joined as Etsy’s

CEO, and was establishing institutional self-discipline to usher in a interval of

development. Mike has a background in scaling high-growth corporations, and alongside

with Martin Abbott wrote a number of books on the subject, together with The Artwork of Scalability

and Scalability Guidelines.

Etsy relied on bodily {hardware} in two knowledge facilities, presenting a number of

scaling challenges. With their anticipated development, it was obvious that the

prices would ramp up rapidly. It affected product groups’ agility as they’d

to plan far upfront for capability. As well as, the information facilities have been

based mostly in a single state, which represented an availability threat. It was clear

they wanted to maneuver onto the cloud rapidly. After an evaluation, Mike and

his staff selected the Google Cloud Platform (GCP) because the cloud companion and

began to plan a program to maneuver their

many methods onto the cloud.

Whereas the cloud migration was taking place, Etsy was rising its enterprise and

its staff. Mike recognized the product supply course of as being one other

potential scaling bottleneck. The autonomy afforded to product groups had

triggered a difficulty: every staff was delivering in numerous methods. Becoming a member of a staff

meant studying a brand new set of practices, which was problematic as Etsy was

hiring many new individuals. As well as, they’d observed a number of product

initiatives that didn’t repay as anticipated. These indicators led management

to re-evaluate the effectiveness of their product planning and supply

processes.

Choosing a companion

Etsy had by no means labored with a software program growth consultancy. To give you the option

to scale product supply and herald some outdoors experience, they began

searching for a vendor. After an intensive search, they chose Thoughtworks,

primarily as a result of they perceived a detailed cultural match and deep alignment

relating to fashionable software program growth.

Thoughtworks has an identical method to Agile as Etsy – being Agile

somewhat than doing Agile. Etsy’s staff was not trying to undertake a

methodology that blindly follows strict rituals and practices, and wished

a companion that bases its method on agile rules and tradition.

Thoughtworks is thought for technical excellence and management in DevOps,

Steady Integration, and Steady Supply, all of which Etsy depends

on closely. As well as, the 2 corporations shared related rules

relating to worker care, range, open-source, and expertise

sustainability.

The Thoughtworks staff began by embedding into product groups, working with

each purchaser and vendor groups, on numerous vital initiatives reminiscent of cost

mannequin modifications, Search Engine Optimization (search engine marketing), and a notification platform.

This enabled Thoughtworks to know how Etsy labored, created a right away

affect on supply, and improved growth practices reminiscent of automated

testing.

For Thoughtworks, Etsy was fairly totally different from the everyday shopper.

They’re a completely digital firm, and their technical course of and product

practises are very mature. Not like most purchasers who interact Thoughtworks,

Etsy had no massive transformation to undertake, and no ingrained habits

that wanted a serious shift. What they have been searching for was outdoors perspective

and supplementive expertise, to assist them incrementally enhance and deal with

their urgent initiatives. The tradition and rules have been already very

aligned with Thoughtworks’ personal, so the partnership turned extra of an

trade of concepts drawn from totally different experiences.

Scaling Product Supply and Discovery

Thoughtworks and Etsy fashioned a cross-functional Product Supply

Tradition (PDC) staff to research the present product supply and discovery

course of. They analyzed the whole software program growth worth stream,

trying intently on the complaints of managers and staff members. Chosen

occasions have been replayed to realize a deep understanding of “how” it occurred

somewhat than who?. The Thoughtworks

staff, as a result of they hadn’t lived by the issues, have been in a position to convey

an goal outsider perspective.

There have been various issues Etsy was doing rather well:

- Cross-functional groups: They structured their groups round “4 desk legs”:

Product, Design, Engineering, and Analytics. All planning and supply practices

occur with collaboration among the many teams. - Incremental supply of worth to customers: Steady supply is the core

apply of their method. A code change sitting in a repository and never

deployed to customers just isn’t invaluable, and successfully prices the corporate cash. Etsy

deploys a whole bunch of instances a day, with a 30-minute decide to manufacturing lead

time. - Options are prioritized utilizing knowledge: Product managers and knowledge analysts

collaborate to find out an anticipated worth, measured by KPI modifications. If the

function doesn’t ship sufficient worth versus its price, as evidenced by an A/B

check, it isn’t rolled out, and the code is eliminated.

The staff additionally uncovered alternatives for enchancment:

- Every staff was doing supply in numerous methods, having disparate processes

and rituals, making onboarding new workers and altering groups troublesome. Some

groups have been utilizing a course of like Scrum, whereas others didn’t use any formal

course of. - There have been various initiatives that had not created worth as

they anticipated. For instance, Etsy tried a present wrap function that had

decrease than anticipated adoption charges by sellers and consumers. - Previous to 2018, Etsy had been by a transitional interval, with

pivots in product technique and management modifications main some product

managers to expres a need for higher possession over their product

selections.

Time to studying

The staff created an enchancment program, based mostly on lean pondering and the

concepts of Marty Cagan, who had lately offered at Etsy. The management staff was

studying his e-book Impressed.

I promise you that not less than half the concepts

in your roadmap are usually not going to ship what you hope. (By the best way, the

actually good groups assume that not less than three quarters of the concepts received’t

carry out like they hope.)

After some preliminary analysis the staff got here up with a metric they referred to as Time

to Studying – the time it took for a product staff to validate an thought with a

buyer and acquire a greater understanding of its worth. They’d a baseline of

50 days that they wished to cut back.

They have been additionally different metrics.

- Bettering the time to market

- Bettering the effectiveness of merchandise (e.g. income, buyer

engagement) - Worker happiness

To affect the KPIs, they got here up with various answer hypotheses:

Lightweight prototypes that incorporate extra direct person analysis

Etsy has sturdy experimentation infrastructure and analytics capabilities.

They run many concurrent A/B exams on {the marketplace}. The issue the PDC

staff noticed is that the suggestions cycle may be fairly sluggish. For an thought to be

prepared for an A/B check it needed to be close to production-level high quality. It additionally had

to have sufficient knowledge to point out statistical relevance. A/B exams would run for

months in lesser-used elements of {the marketplace}.

To set your expectations, sturdy groups usually

check many product concepts every week—on the order of 10 to twenty or extra per week. I

need to emphasize that these are experiments, sometimes run utilizing prototypes.

A prototype just isn’t one thing that’s prepared for prime time and definitely not

one thing your organization would attempt to promote and stand behind. However they’re

immensely helpful, as they’re all about studying quick and low cost.

To scale back the Time to Studying metric, the PDC staff utilized a lean UX

method. First, they began by rapidly creating lo-fi prototypes and

instantly displaying them to customers. Second, the staff elevated person suggestions

classes to each two weeks and diminished the extent of ceremony. Third, they

created a dual-track system, with a design and analysis staff frequently

working forward of a supply staff. The concept was to effectively acquire confidence

in an thought earlier than it qualifies for an A/B check. By decreasing the price of

experimentation, they might enhance the variability and amount of experiments,

discovering concepts that confirmed extra worth.

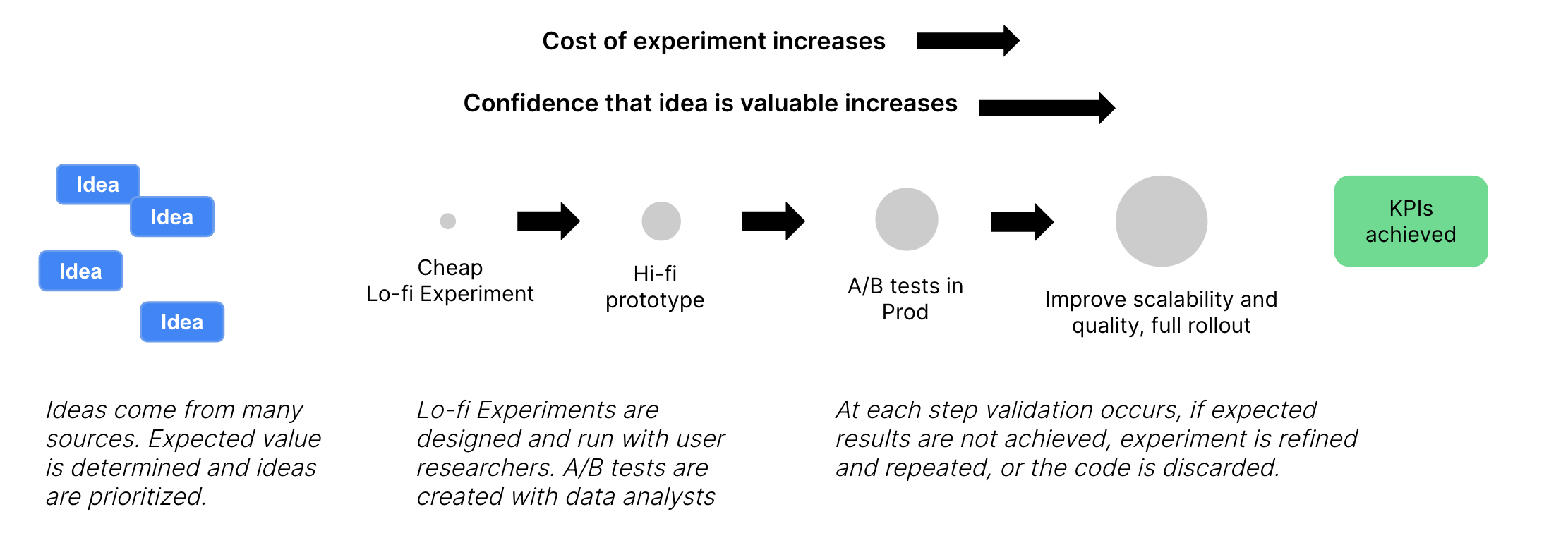

Determine 1: Experiment validation course of

Blueprint for product supply

The PDC, at the side of product staff leaders, got here up with a set of

product supply rules and associated supply apply modifications. The

practices included: smaller extra centered tales, redesigning story partitions to

higher match the staff course of, utilizing spikes to cut back technical uncertainty, and

higher methods of managing tech debt. They didn’t need to take away the autonomy of

groups. Steady enchancment is a giant a part of Etsy tradition. These practices

are supposed to be handled as smart defaults that may be tailored and improved

for every staff’s particular context.

The PDC staff first examined the apply modifications on pilot product groups to

set up their effectiveness after which iterated. As soon as the apply

demonstrated an enchancment, the staff added to a data base and supplied

gentle teaching to introduce the brand new practices to all product groups throughout

Etsy.

Lean Portfolio administration

Some massive initiatives have been nonetheless being carried out, although there was

not clear proof of the initiative creating worth. That is the everyday sunk

price drawback. To unravel this, the PDC staff

urged taking a lean method to portfolio administration.

Our runway must be an inventory of hypotheses to check, not an inventory of

necessities to construct. After we reward our groups for his or her skill to ship

necessities, it’s simple to quickly bloat our merchandise with pointless

options—resulting in elevated complexity, increased upkeep prices, and

restricted skill to alter. Options delivered are usually not a measure of success,

enterprise outcomes are. Our runway is a sequence of questions that we have to

check to cut back uncertainty and enhance our understanding of development

alternatives.

As a substitute of making prolonged undertaking specs and plans, the PDC staff

coached product groups to develop consequence statements for every initiative. With

consequence statements, beginning with a buyer or enterprise consequence permits the

staff to experiment with many alternative concepts to realize the result by tying

them to measurable KPIs. The much less exact an consequence is, together with its KPIs,

the more durable it’s to specify. When getting ready for potential initiatives, every

product staff created a two-page transient summarizing the result, the measurable

affect, and the preliminary funding required.

The manager staff prioritized the result statements, and every assertion

was considered as a “guess” amongst a portfolio. Impressed by the Lean Worth Tree

idea, the manager staff would apply a daily cadence to find out if a

guess was paying off, giving them the chance to pivot early.

Determine 2: An instance initiative assertion

Stronger product & engineering collaboration

One other enchancment was to incorporate engineers early within the product ideation

course of and to have them be part of person suggestions classes. The staff examined

engineers becoming a member of the speculation era and validation classes and

working intently with designers throughout design sprints. The outcomes of the check

confirmed an a variety of benefits. Engineers improved their understanding of the

buyer, constructing empathy for his or her wants. They may present on-the-spot

suggestions on the feasibility of an method and rapidly create prototypes to

display concepts to customers. Cross-functional engagement allowed engineers to

contribute various nice concepts that made it to the product.

After the preliminary PDC initiative Etsy continued to strengthen the

collaboration between teams. At each degree of the group, product and

engineering are companions, which implies they’re in a position to have wholesome trade-off

discussions. The platform group expanded using product managers for

infrastructure and developer tooling groups – encouraging groups to consider

technical capabilities as merchandise and end-users being Etsy engineers. The

technical product managers do analysis and prioritization actions, simply as

they’d for a buyer product.

What was the affect of product supply tradition?

Testing with pilot groups indicated that the Time to Studying went from 50

days to five days. Through the pilot, one product supervisor stated, “What I really like about

the [direct user research sessions] pilot is that it lets us check our concepts

quicker, it was very nice to not spend as a lot time diving deep into

one thing that we didn’t even know we have been going to make use of.” An initiative on

stock high quality that was predicted to ship a seven million greenback income

enhance as a substitute delivered eleven million {dollars} in incremental worth utilizing

the PDC urged enhancements. Following this pilot success, the staff coached

the whole product growth group on the product supply method.

In keeping with Mike Fisher, “It is vitally exhausting to isolate the advantages of a

course of change on a company of a number of hundred engineers since we don’t

run A/B experiments of this sort. Nevertheless, we did take a look at excessive degree

productiveness metrics after having PDC carried out for over 2 years, and all of

our metrics have been very optimistic. We had improved our velocity by doing this

work, and we have been in a position to produce in the end extra advantages for the consumers and

sellers – extra options, higher search, higher processes; the entire

market turned higher for consumers and sellers and that was the objective.”

[ad_2]